Retrofit

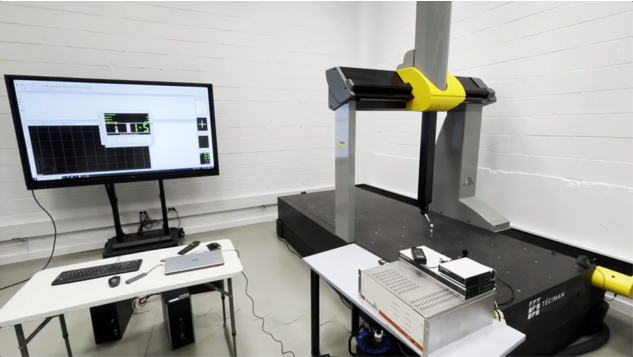

Téciman updates any MMC From the market, both in hardware like in software and with 1 year warranty.

From software-only updates to the complete reconstruction of machinery, including the replacement and adjustment of mechanical and pneumatic elements.

Comprehensive machine support, regardless of software.

Some retrofits carried out

Coord3 Swan L 40.18.20 CNC

Purchased by the customer at auction. Electronics installation. Renishaw UCCT3+. TouchDmis CAD software.

Mitutoyo EuroC A9106 CNC

Change of reading rules. Control installation. Renishaw UCCT3+ and TouchDMIS CAD. The old continuous probing probe is used. Renishaw SP600.

Zeiss Eclipse 700 7.7.6 CNC

Motorized replacement. New reading gifts. Pantec electronic installation and Metrolog x4 software.

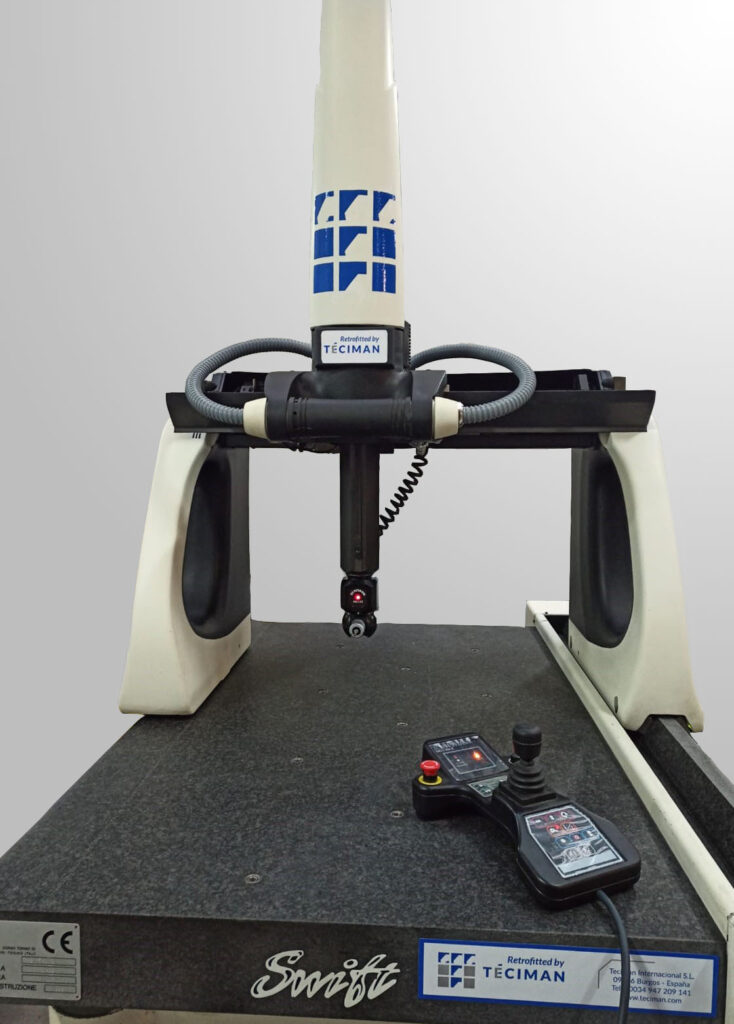

DEA Swift A.001 CNC

Comprehensive retrofit. Installation of Renishaw control and TouchDMIS CAD software. Installation of robotic head with 2 additional rotation axes.

Zeiss PMC 850 CNC

Robotic head upgrade to Renishaw PH10M. Replacement of reading rules, wiring and pneumatic system. Polyworks installation on Renishaw electronics. UCCT3+.

Types of retrofits

We use electronic of Metrologic Group, Renishaw, Pantec, Chameleon.

Through electronics Chameleon, the retrofit is independent of the software: PC-DMIS, MCosmos, TouchDmis…

The software what we install are Metrolog X4, Polyworks, TouchDmis, Modus…

- Software update and complete machinery reconstruction.

- Replacement, modernization and adjustment of mechanical and pneumatic elements; fundamental for good geometry of the CMM.

- Complete rewiring of the three-dimensional machine. Replacement of reading rules and probes.

- Review and adjustment of servomotors and CNC controllers.

- Update and enhancement of the probing system, with continuous scanning and/or digitization technology.

- Large stock of discontinued electronic spare parts and new compatible 100% controls.

We get

- Extend the life of your coordinate measuring machine (CMM).

- Economic savings compared to the acquisition of a new CMM.

- Faster and more flexible delivery time.

- Improve measurement systems. Thus increasing productivity.

- Get more security in the long term.

- Possibility of adding all types of new technologies such as probing sensors, scanners, inspection accessories... and thus optimize your measurement processes. And improve the precision and repeatability of the system.

Advantages over second-hand CMMs

- Warranty.

-

Buying experience equivalent to new.

Turnkey, cost control, no surprises, transfer, calibration, installation, training, etc. - Life expectancy of the renewed equipment of 20 years.

-

Configurable.

Choice of accessories, software, etc. - Eligible.

- More economical (25-50%).

- Reduced delivery time.

Updated MMCs

- Mitutoyo EuroC A544

- Stieffelmayer Manual 12.25.15

- Wenzel 15.10.08 CNC

- DEA Global 9.15.8 CNC

- DEA Swift A.001 CNC

- Zeiss PMC 850 CNC

- Coord3 Swan SI CNC

- DEA B&S Gage 2000 Man

- DEA B&S Microval PFx 454 CNC

- AED Iota Manual

- Trimek Spark 15.8.6 CNC

- Zeiss Eclipse700 7.7.6 CNC

- DEA Swift A.001 Man

- Tesa Micro-Hite DCC

- Coord3 Ares 10.7.5 CNC

- DEA Epsilon 14.19.14 CNC

- DEA Global Classic CNC 575

- Trimek TL 20.15.15 CNC

- Mitutoyo Crysta Apex 7.10.6 CNC

- Lateral default 33.18.18 CNC

- Coord3 Swan L 40.18.20 CNC

- Mitutoyo EuroC A9106 CNC

- DEA Global 12.22.10 CNC

- Coord3 Ares 775 CNC

- B&S Chameleon 30.14.08 CNC

- DEA Mistral 10.7.5 CNC

- Coord3 Hera 12.9.8 CNC

- Trimek Spark 12.8.6 CNC

- ...