Teciman has developed a file export system DMIS to PIWEB. This enables a global overview of the dimensional control of the parts. The new application allows all measurement data to be collected regardless of the software used. It also enables the creation of a single database for statistical control.

The client turns to Téciman to adapt its dimensional control system to the company's new requirements. Our metrologists propose to implement the software Polyworks on a three-dimensional measuring machine and a new export system. This enables the transfer of results to the group's overall database.

How did we do it?

To implement this solution, we performed the retrofit of the arm-type coordinate measuring machine (with measuring volume 2000x1000x1500). This involves the replacement of worn elements, mechanical adjustment, renewal of electronics and sensors, and the installation of the measurement software mentioned above. Finally, the ENAC calibration.

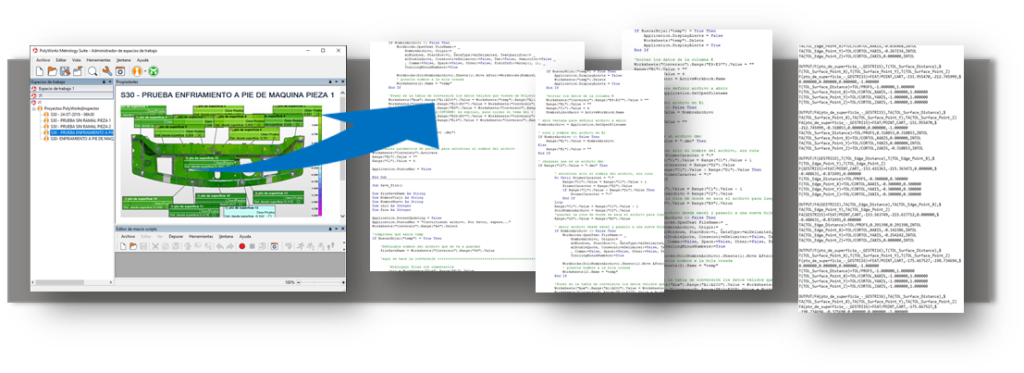

But the main challenge of the project was to export the data obtained from the Polyworks measurement to PIWEB. The strategy was to perform a previous export step to the DMIS standard using Polyworks' own macros. The conversion system was then developed. This was possible by using scripts, thus converting the DMIS file to a format recognized by PIWEB and with the configuration defined by the client.

Finally, Téciman carried out the training to the client's metrology team. Knowledge was imparted on the use of the system and on metrology in general.

Thanks to this new export system, the client saves time transcribing data. The time that the metrology team previously wasted on this action is now used to check a larger number of parts. Quality control at the plant has been greatly improved.