«Téciman, a 3D Engineering and Metrology company from Burgos, delves into the reverse engineering in this way being able to create parts for machines, also for which there are no longer spare parts" is how the article published by El Correo begins, in the section Innovators.

Today the article has seen the light in which Iñigo Moreno, commercial and marketing director of Téciman, and María Merino, editor of El Correo, have collaborated, revealing all the advantages and applications of this technology. Full news below:

In this incredible world of technological innovation, Reverse engineering emerges as an invaluable tool to address the challenge of sustainability. Instead of relegating obsolete products to oblivion, reverse engineering makes it possible to unravel their components and recreate parts that are no longer manufactured, and for which there are not even measurements, or technical sheets. This ingenious approach not only extends the life of the products, but allows them to be updated, and reduces the need to manufacture new machinery, thus contributing to a more sustainable and environmentally friendly world.

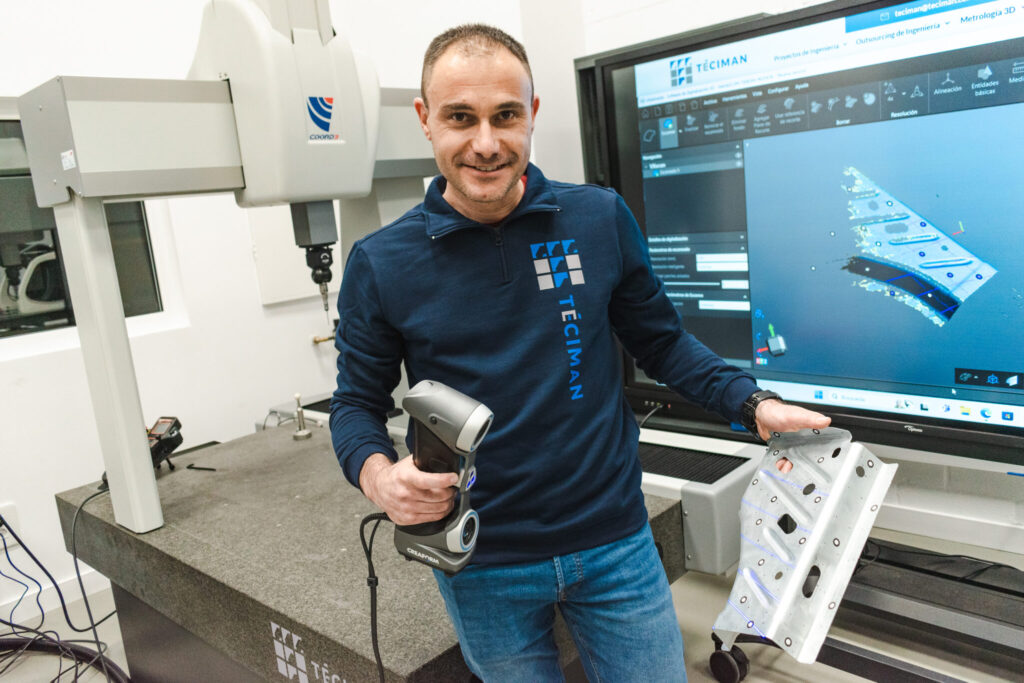

Téciman is a multidisciplinary, innovative company from Burgos with international reach, whose latest project focuses on this field. Inigo Moreno, commercial and marketing director of Téciman, gives us the keys to better understand their solutions in this technological field.

As Moreno explains, Téciman was born in 1991 focusing its efforts on Industrial Consulting and 3D Metrology. to respond to the demanding needs of the sector. After a short period of time, it positioned itself as leading company in the field of Coordinate Measuring Machines (MMC) and 3D Measurement. Téciman's measurement capabilities grew exponentially, innovating its Metrology Laboratory with the most advanced technologies. Currently, your team is made up of more than 70 people experts in different fields.

After more than 30 years, This Burgos company comprises three business units, such as 3D Metrology, Engineering Projects and Engineering Outsourcing.

According to the 3D Metrology, Moreno points out that they are experts in ENAC calibration, retrofit and maintenance of Coordinate Measuring Machines. They have a wide catalog of Coord3 and Renewed Three-Dimensional Machines, the latter updated by their own technicians. They have measuring equipment and metrologists experts in various software (Metrolog, Polyworks, PCDMIS, Cosmos, TouchDMIS, …) and systems (with or without contact), used to provide service in different sectors of activity.

In the unit Engineering Projects they are in charge of the management, development and execution of engineering projects, based on the client's specifications, to deliver a totally optimal, functional and quality final project. Count on extensive experience in Industrial Automation, Design and Simulation, Special Machines and Tools and Control Models.

As for the Engineering Outsourcing, Moreno affirms that they are integrated into the structure of each project, providing the specific engineering capabilities required in it. Count on experience in very different sectors such as Railway, Energy, Automobile, Aerospace, Defense and Industrial.

Its latest project, reverse engineering, has been possible thanks to the collaboration between its areas of Engineering Projects and 3D Metrology.

Reverse engineering is the best solution when it is needed replicate a piece, but there are no plans to do so. That is, when there is no prior CAD or it is insufficient, says Moreno.

The process of creating a component thanks to reverse engineering consists of scan the part obtaining a cloud of points to create a polygonal model (in 'stl' format) that includes the 'skin' of the piece or surface.

From this cloud of points, we work from the design area for withpour it into a solid that can be edited with CAD software (Solidworks, Inventor, Catia…). Once obtained, this 3D model is used to create 2D manufacturing plans.

The piece in question can be replicated in any type of materialsays Moreno, since what is obtained at the end of the process is a CAD design, which is independent of the manufacturing process to be used. It can be used to reproduce it in a 3D printer, in a machining center, in the creation of a mold for casting or injection, etc. So this process ends with a versatility applicable to countless machines.

The applications are diverse; one of them is create CAD models of existing parts or components, this is useful for the manufacture of spare parts or for improving the design of a component. Another is that of analyze and improve the design of a component obtaining detailed information about its design and operation. Helps identify potential problems and improve component design. It is also used for update or replace obsolete parts not available on the market. Reverse engineering can be used to recreate these parts obtaining functional spare parts.

And lastly, this process can create tool models for the manufacture of related parts or components.

The company team fully recognizes the immense savings and remarkable efficiency which entails the ability to update obsolete components within systems and machinery. This practice not only provides new life to equipment that might otherwise end up being scrapped, but also represents a significant contribution to industrial sustainability and environmental care.

In this context, a fundamental part of Téciman's work focuses on comprehensive modernization or retrofit of three-dimensional measuring machines. By focusing on updating the electronic part, these machines are transformed, offering solutions with the same quality standard and guarantee as a completely new machine. Moreno points out that this approach not only prolongs the useful life of the equipment, but also reduces waste generation and promotes more responsible management of industrial resources, while maximizing the return on investment for each client.

Currently, Téciman is carrying out a more robust approach to the development of automation projects. In the area of quality control, for example, they are using 3D scanners to inspect in an automated manner, using robots, that the manufactured parts comply with the standards established in the design, according to Moreno. Likewise, they are making improvements to the manufacturing lines, through the incorporation of automation and updating to technologies more modern and more efficient solutions.