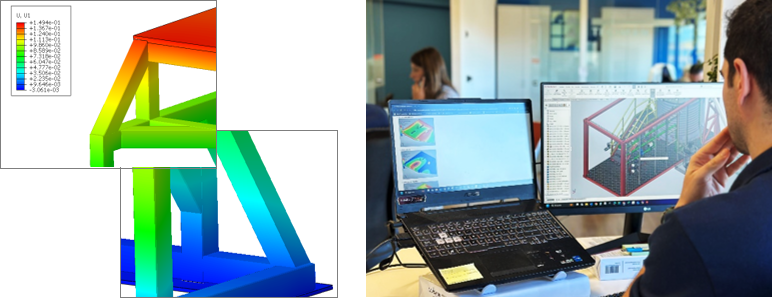

Teciman perform the finite element design and calculation of a robot support structure located in a frozen food plant, in an environment of -25ºC.

Context: installing a robot at extreme temperatures

The client needs a structure suited to the plant's layout and temperature to ensure proper positioning and movement of the robot. And this is where we come in.

The overall project involves installing a robot to load and unload boxes onto various conveyor lines in a food processing plant.

Precise design and calculation for an efficient structure

Our engineers carry out the structure design according to the layout of the plant which, due to the limited space, is asymmetrical and with cantilevers.

Due to the complexity of the shape and the thermal changes, it is necessary to carry out a numerical simulation of structural behavior of the frame. Analyzing the stress state and displacements.

This analysis confirms the importance of paying attention to weld execution to avoid failures, particularly in the welding of the joint perimeter and minimum weld thicknesses.

Material selection and assembly strategy

As for temperature, it is determined that the steel used is sufficient. Although our calculation team recommends more suitable special materials for extreme cold conditions.

Finally, to ensure proper frame assembly, it was decided to secure only one of the bolts. This method allows the structure to contract freely until it reaches plant temperature (-25°C), at which point the remaining bolts are installed.

The key: iterations between Design and Calculation for the optimal solution

Our Technical Office carries out several iterations between the structural design and calculation (redesigns, thickness changes, material analysis, etc.), advising our collaborator to deliver the optimal solution to the end customer.

For more information about our capabilities call us at 947 20 91 41 or send us an email to teciman@teciman.com. Follow us on LinkedIn to find out all the news.