Metrology software ensures measurement accuracy and quality control across a variety of industries. It performs everything from part inspection to comparison with CAD models and generation of detailed reports.

5 Main Measurement Softwares on the Market

PC-DMIS (Hexagon)

It allows you to create automated measurement routines, perform advanced data analysis, automate inspection routines, and has powerful CAD integration. It is compatible with devices such as portable measuring arms and laser scanners.

Despite being one of the most popular metrology software, it has compatibility and stability issues with some devices and older versions of the software. Accompanied by slow support and updates service. In addition, it requires a high investment in hardware to ensure smooth performance of the software.

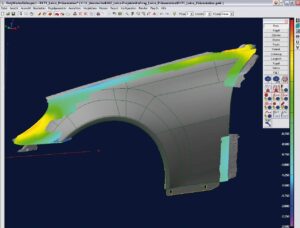

PolyWorks (InnovMetric)

It stands out for its versatility, being able to act on all types of surfaces. It covers the complete product development cycle, from the design and prototyping of parts and tooling to the final inspection of assembled products. It has advanced inspection capabilities that allow you to identify and correct deviations, evaluate product quality and make comparisons with CAD models.

Requires extensive training to take advantage of all its features. It is a high-end solution so it may not be accessible to small and medium-sized businesses with low budgets.

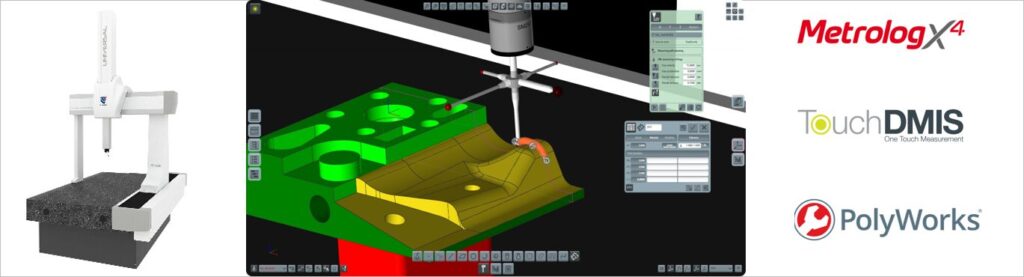

Metrolog X4 (Metrologic Group)

It is a set of solutions of 3D metrology, simulation and robotic inspection, compatible with Catia v5 and 3D measurement devices. It has an architecture optimized for working with large volumes of data, which guarantees precise and high-quality results. It has an intuitive interface, with advanced tools, and offers the capacity for simulation and robotic inspection.

It can be considered less intuitive compared to other metrology software and generate a less fluid user experience.

Calypso (Zeiss)

It is a software that stands out for its advanced capabilities for complex measurements. It offers a solid integration with CAD models, allowing direct import and accurate comparison between theoretical models and measured parts. It does not require a long learning curve.

It creates a clear dependency on the Zeiss ecosystem, so if equipment from different manufacturers is used, it may not take full advantage of the software and face integration challenges. The options for advanced customization are very limited, which can cause problems for companies that need to adapt the software to unique processes.

TouchDMIS

TouchDMIS stands out for its Easy to use and his compatibility with a multitude of equipment, whether by probing or laser scanning. It allows you to program and execute complex measurements in a clear and functional way. It has a step-by-step guide and visual feedback in real time, which allows you to optimize measurement processes, reduce programming times and obtain reliable results. Based on international standards.

Because it's designed to be easy to use, it doesn't have as many advanced features as more complex software. Its simplified interface can be an advantage for new users, but also a disadvantage for advanced users who need more control and customization options.

TOP 3 measurement software according to Téciman

We have extensive experience in using the main metrology software developers. Below we tell you about our Partner and the reasons why we chose them:

Metrolog X4

- Customizable

- Windows with multiple information

- Automatic orientation during point acquisition

TouchDMIS

- DMIS Programming Language – ISO 22093

- Tolerancing – ISO 2768

- CAD File Import/Export STEP – ISO 10303

- I++ DME Communication Protocol

PolyWorks

- Flexible and customizable

- Versatile and easy-to-use macro script programming

- Assisted sequencing

Technical support and updates: a key aspect in measurement software

Technical support and software updates are crucial to ensure optimal operation of 3D measuring machines and maintain accuracy and efficiency in inspection and quality control processes.

Some aspects that highlight the importance of this service:

- Guarantee of precision and reliability. Software updates often include improvements to measurement algorithms and bug fixes that ensure CMMs perform measurements with the highest possible accuracy.

- Compatibility with new devices and technologies. Ongoing support and updates allow the software to be compatible with new hardware versions and other emerging technologies.

- Process optimization and efficiency. Software updates often include improvements to the user interface, routine automation, and other features that optimize machine use.

- Reduced downtime. Effective technical support can prevent and resolve problems quickly, minimizing machine downtime.

- Support for customization and adaptation. It allows the software to be adjusted to suit the specific needs of the company, optimising the operation of coordinate measuring machines for particular tasks.

At Téciman we offer a fast and flexible technical support service for three-dimensional measuring machines and measurement software, avoiding machine downtime and production problems. For more information, please visit our website (www.teciman.com), call us at 947 20 91 41 or send an email to teciman@teciman.com. Follow us on LinkedIn to find out all the news.