¿En qué consiste la Ingeniería Inversa?

La ingeniería inversa es la mejor solución cuando se necesita replicar una pieza, pero no se disponen de planos para hacerlo. Es decir, cuando no existe un CAD previo o es insuficiente.

Procedimiento: Desde el escaneado hasta el sólido 3D

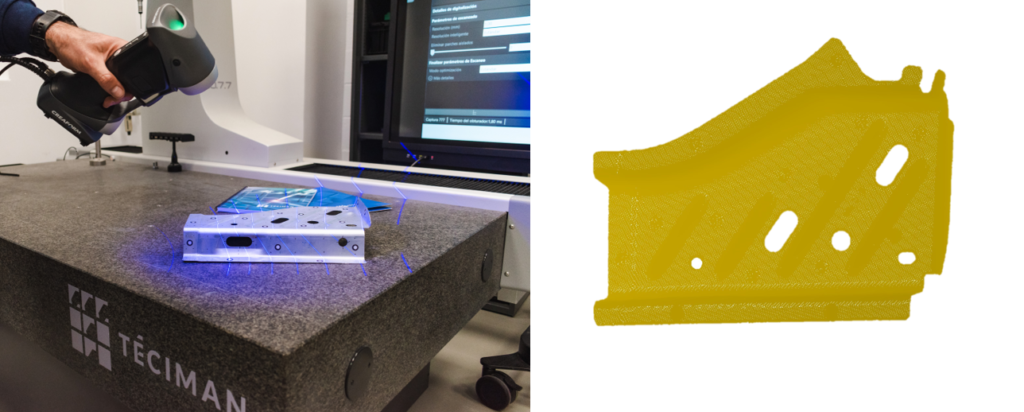

El proceso de creación de un componente gracias a la ingeniería inversa consiste en escanear la pieza obteniendo una nube de puntos para crear un modelo poligonal (en formato ‘stl’) que comprenda la ‘piel’ de la pieza o superficie.

A partir de esta nube de puntos, se trabaja desde el área de Diseño para convertirlo en un sólido que pueda ser editado con los software de CAD (Solidworks, Inventor, Catia…). Una vez obtenido, este modelo 3D sirvepara crear los planos 2D de fabricación.

Versatilidad del resultado

La pieza en cuestión se puede replicar en cualquier tipo de material, ya que lo que se obtiene al final del proceso es un diseño CAD es independiente del proceso de fabricación a usar.

Puede ser utilizado para reproducirlo en una impresora 3D, en un centro de mecanizado, en la creación de un molde para fundición o inyección, etc. Por lo que este proceso goza de un final con una versatilidad aplicable a infinidad de máquinas.

5 Ventajas de la Ingeniería Inversa

- Permite la creación de modelos CAD precisos sin necesidad de tener los planos originales.

- Ahorra tiempo y costos, mejorando el diseño existente en lugar de crear uno nuevo desde cero.

- Facilita la fabricación de piezas personalizadas, que es útil para la reparación de equipos antiguos.

- Posibilita la identificación de problemas y fallas en su diseño y funcionamiento, ayudando a mejorarlo.

- Permite la actualización de equipos antiguos para recrear piezas obsoletas extendiendo su vida útil y evitando la necesidad de reemplazar todo el equipo.

Aplicaciones de la Ingeniería Inversa

Las aplicaciones son diversas, a continuación las mas comunes:

- Crear modelos CAD de piezas o componentes existentes

Esta tecnología es muy útil para la fabricación de piezas de repuesto o para la mejora del diseño de un componente.

- Analizar y mejorar el diseño

A través de la información detallada obtenida sobre su diseño y funcionamiento se puede identificar posibles problemas y mejorar el diseño del componente.

- Actualizar o reemplazar piezas obsoletas

También se utiliza para actualizar o reemplazar piezas obsoletas no disponibles en el mercado. La ingeniería inversa puede ser utilizada para recrear estas piezas obteniendo repuestos funcionales.

- Crear modelos de herramientas

Y por último, este proceso puede crear modelos de herramientas para la fabricación de piezas o componentes relacionados.

Metrología 3D y Diseño, cooperación para Ingeniería Inversa

Medición o escaneado, área de Metrología 3D

Los técnicos del área de Metrología 3D realizan el escaneo de la pieza obteniendo la nube de puntos (modelo 1). Y partiendo de esta nube crean un modelo poligonal en formato “stl” (modelo 2). Dicho formato comprende la piel de la pieza o superficie.

Modelo 3D, área de Diseño y Simulación

Para generar el modelo 3D sólido de la pieza (similar a uno realizado mediante Solidworks, Inventor, Catia…) entra en juego la unidad de Diseño y Simulación. Mediante softwares específicos se realiza el modelizado CAD, obteniendo el 3D. Este modelo (3) puede ser modificado y trabajado mediante cualquier software CAD/CAM para su posterior fabricación.

La Sostenibilidad y Téciman

Es relevante destacar el notable ahorro y eficiencia que conlleva la capacidad de actualizar componentes obsoletos dentro de sistemas y maquinarias. Representa una contribución significativa a la sostenibilidad industrial y al cuidado del medio ambiente.

En este contexto, una parte fundamental de la labor de Téciman se centra en la modernización integral o retrofit de máquinas de medición tridimensional.

Al enfocarse en la actualización de la parte electrónica, se transforman estas máquinas, ofreciendo soluciones con el mismo estándar de calidad y garantía que una máquina completamente nueva, lo que consigue:

- Prolongar la vida útil de los equipos

- Reducir la generación de residuos

- Promover una gestión más responsable de los recursos industriales, al tiempo que se maximiza el retorno de inversión para cada cliente

Si te interesa este tipo de contenido síguenos en LinkedIn Téciman_International donde publicamos contenido semanal referente a la Metrología 3D, Automatización Industrial, Diseño y Simulación… Contáctanos mediante la web, en el correo teciman@teciman.com o llamando al 947 20 91 41