There is a wide variety of accessories that optimize the performance and versatility of the Three-Dimensional Measuring Machine.

This article analyzes the feelers, probe modules and fixing tools. Each is designed to improve accuracy, adaptability and efficiency during the inspection process.

Probes for Three-Dimensional Measuring Machine

The probes detect the exact position of the part coordinates and transmit this information to the machine, allowing for accurate metrological analysis.

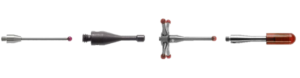

Types of precision probes

- Straight: It is the simplest and most widely used probe, suitable for most inspection applications.

- Cylinder: Used to inspect sheet metal, pressed components, and thin workpieces.

- Star: A configuration of multiple probes in a fixed mount. Used to inspect a variety of different features.

- Cylindrical probe with a hemispherical tip: suitable for measuring deep surfaces and pockets in the X, Y and Z directions, indicating the reference plane only on one ball.

- Disk: They are used to feel notches and grooves in internal diameters that could not be accessed with a star probe.

- Hemispherical: suitable for measuring deep surfaces and pockets in the X, Y and Z directions, indicating the reference plane only on one ball.

- Data: Tool setting probes have a square, polished tip to ensure high squareness and parallelism.

- On point: Designed to inspect threaded forms, specific points and scribed lines.

- Extensions: available in different lengths and materials: steel, titanium, aluminum, ceramic and carbon fiber.

Considerations when choosing a probe

- Type of piece and surface: the shape and material of the object to be measured must be taken into account.

- Length and stiffness: A stylus that is too long or heavy can affect accuracy, so there must be a balance between reach and stability.

- Periodic calibration: It is essential to recalibrate CMMs after installing or changing probes to maintain measurement accuracy.

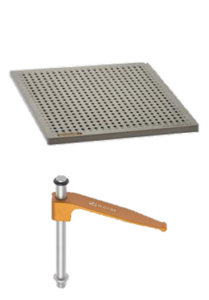

Fixtures for Three-Dimensional Measuring Machines and Gauge Systems

These components facilitate the clamping of workpieces of almost any size, shape or material on the measuring table. They are designed for Three-Dimensional Measuring Machine and calibration systems. Equator, include: plates in standard sizes, parts compatible with M4, M6, M8 and 1/4-20 threads…

Types of metrological fixing tools

- Kits Preconfigured for easy start-up

- Plates with different threaded holes M4, M6 and M8 of different sizes and materials

- Spacers and magnets to lift and place the pieces

- Tweezers and adjustable to hold the workpieces flexibly

- Towers to hold large components or workpieces vertically

- Others: cones, support pins, corner viewers…

Probe Modules for Three-Dimensional Measuring Machine

These interchangeable devices extend the functionality of the probes, optimizing the inspection in terms of precision, accessibility and speed.

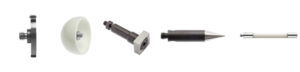

Types of probe modules

- TP200 probe modules: Compact contact trigger probe with strain gauge mechanisms, with much greater accuracy and life than kinematic contact trigger probes.

- TP20 probe modules: They provide a range of activation forces that allow the best probe performance to be adjusted according to the measurement task.

- SP25M Probe Modules: scanning probe and a touch trigger probe using the TP20 probe modules.

Téciman is Renishaw Channel Partner

Téciman collaborates with renowned manufacturers such as Renishaw to provide a wide range of accessories for Three-Dimensional Measuring Machines.

Renishaw has driven innovations that have revolutionised industrial metrology. From the first touch probes and motorised steerable heads to automatic stylus loaders and modular measurement systems, its sensors for coordinate measuring machines (CMMs) have established themselves as the industry standard, compatible with all brands. Its range of five-axis measurement solutions represent a significant step forward in performance, offering unprecedented speeds and unrivalled flexibility.

Distribution of accessories for CCM

- Extension bars: Increase reach to reach deep parts with minimal loss of accuracy.

- Probe supports: to expand the inspection system with different lengths and functions.

- Changing tables: Provide flexibility to change the probe and sensor of the inspection system.

- Calibration spheres: allows periodic recalibration of the probe.

- Probes: capture precise points on the surface of the part by contact or scanning.

- Probe modules: They facilitate the rapid exchange of probes to adapt to different applications.

- Fixing tools: Increase repeatability and accuracy by ensuring the part is in the correct position.

For more information on accessories or spare parts for Coordinate Measuring Machines, please consult our web, call us at 947 20 91 41 or send an email to teciman@teciman.com. Follow us on LinkedIn to find out all the news.