From Teciman We tell you how, thanks to the service of retrofitAn obsolete measuring machine can be converted into a new one with the 95%. With all the advantages that this implies.

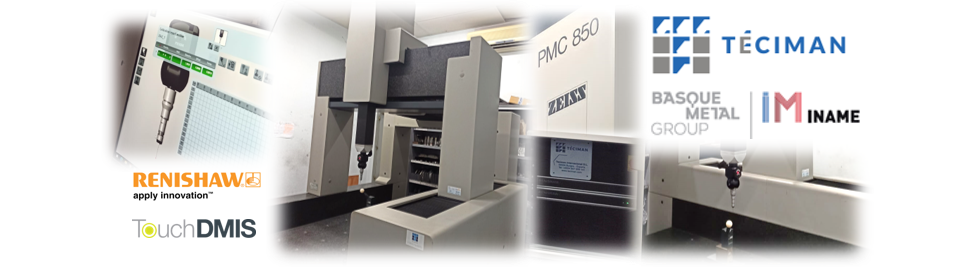

As an example of a recent case, our technicians performed a Full update from the coordinate measuring machine (MMC) ZEISS PMC 850 making it fully operational and with software installation TouchDMIS. This project was a challenge due to the age of the machine, which dates back to the 1980s.

The client's objective, Iname Industries – machining company belonging to Basque Metal Group, was to make operational a three-dimensional machine of great value that had fallen into disuse over the years. The work was fully developed on site, at the client's facilities in Navarra.

Procedure carried out:

First, Téciman's technical team, made a in-depth review of the mechanical part of the machine. Replacing the necessary elements (belts, pneumatic tube, cleaning of skates and guides, etc.) to achieve its correct operation.

After, the electronics were updated to Renishaw UCC, together with the reading rules and the encoders with Renishaw 0.1 µm resolution.

Subsequently, the software was installed TouchDMIS CAD at the latest level, thus achieving all the capabilities of modern software and the ease of use of TouchDMIS.

To achieve better functionality A robotic head was added Renishaw PH10M with additional rotation axes. In addition, a automatic changer of TP20 probe modules, model Renishaw MCR20. These latest improvements are due to the fact that the three-dimensional machine had a fixed head as standard, which meant that it could not orient the probes, thus limiting its performance.