Design and Simulation

We have professional CAD and CAE software as well as a team of highly qualified engineers to offer personalized design and simulation solutions.

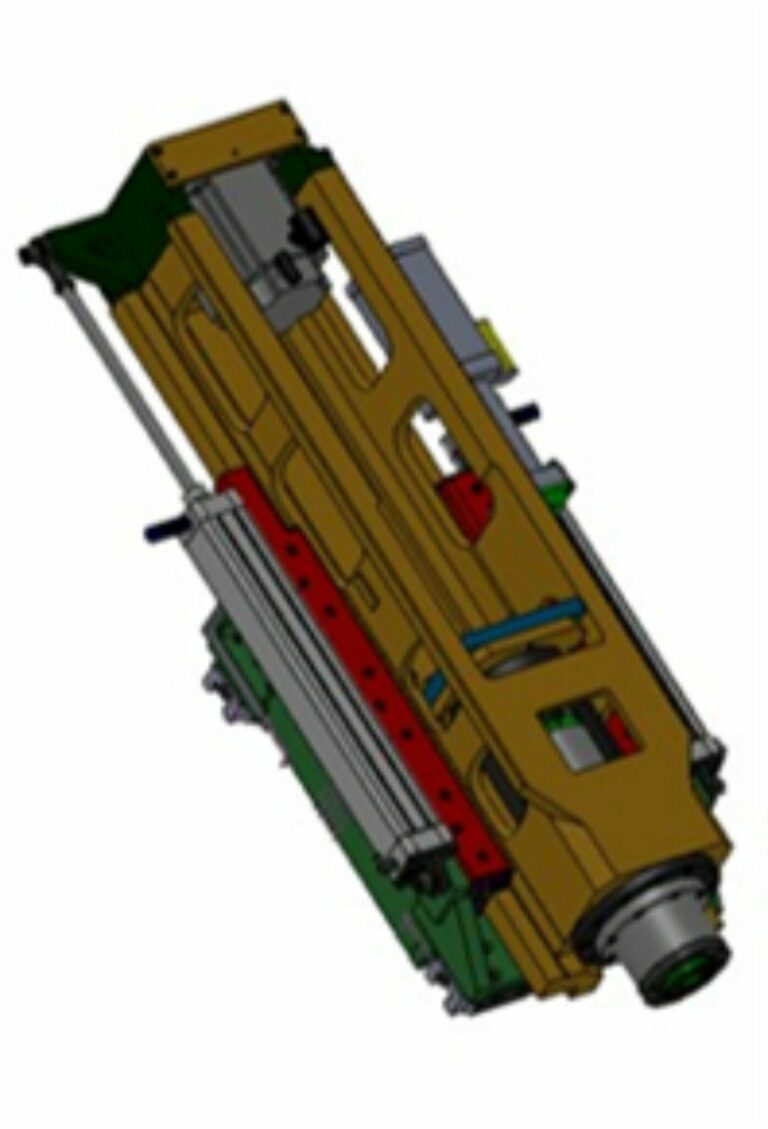

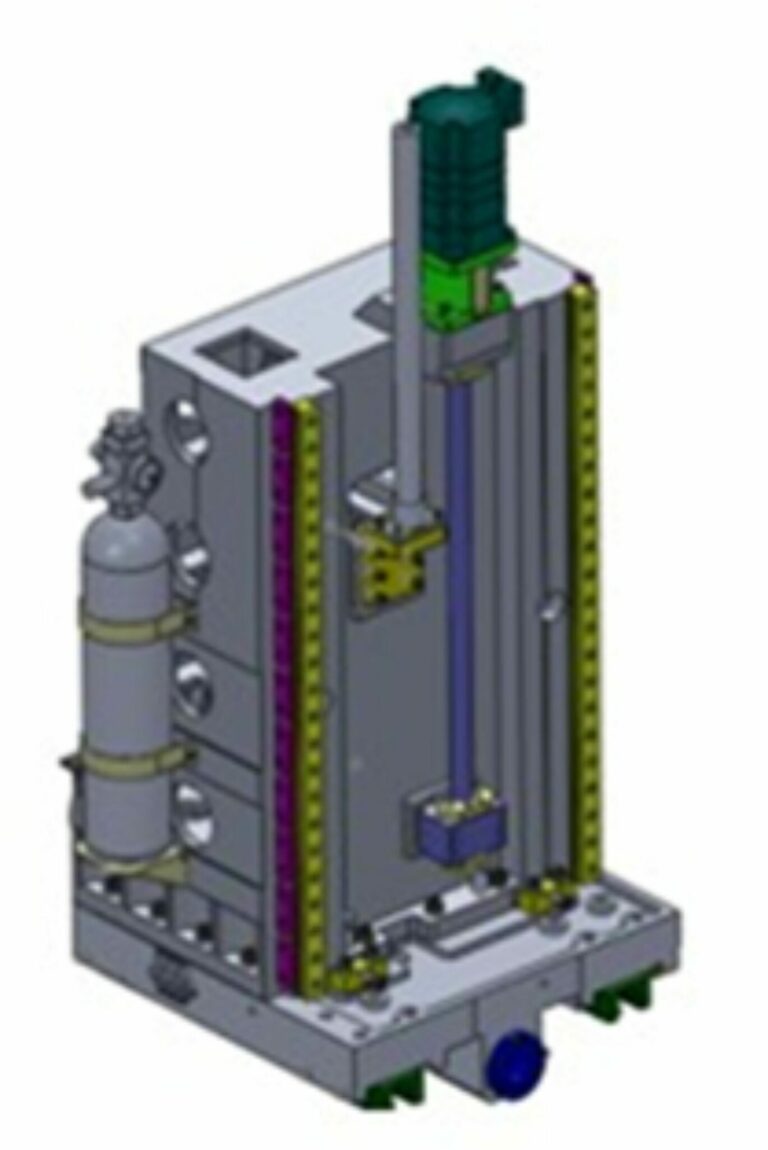

CAD Mechanical Design

We carry out under computer-aided design (CAD), the development of new products even to improve existing ones. We create three-dimensional models of parts and assemblies to visualize the final product. And make it possible to make the appropriate modifications to the part before its production.

Services

Generation of part and assembly models

We design three-dimensional models of parts and assemblies, simple and complex, guaranteeing their feasibility, including the dimensions, tolerances and annotations necessary for manufacturing.

Piping design

We configure and design piping and conduit systems for optimal fluid flow.

Delineation of 2D manufacturing drawings and management of CAD Data

We deliver all the documentation in 2D plans, necessary for the manufacturing of parts or document management of the project. We can integrate with the client's manufacturing systems.

Reverse Engineering and Design Optimization

We can recreate existing components in cases where the original plans are not available using the 3D scanning.

Examples

Plastic or metal parts, sheets, welded parts, special surfaces, molds and dies, handling systems, machinery, etc.

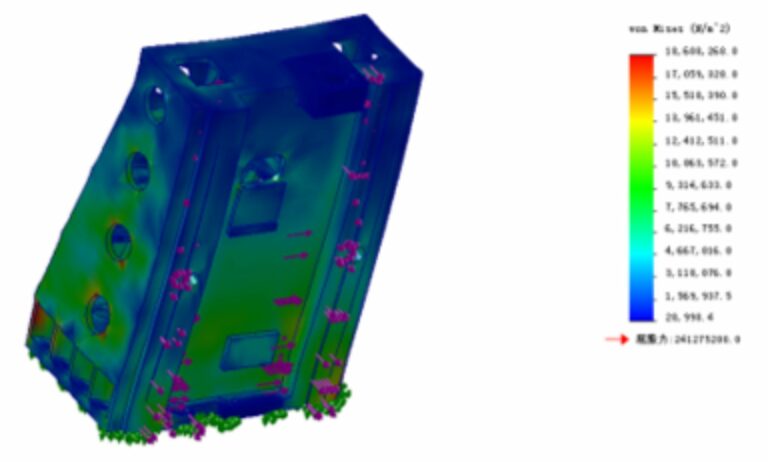

CAE simulation

We carry out engineering simulation (CAE) to predict how a product or system will behave in real working conditions. This is how we analyze how a product will withstand loads, vibrations, temperatures and other factors to ensure that it will meet performance and reliability requirements.

Simulation also allows us identify possible problems before production, saving development time and costs.

We work

- Simulation of Manufacturing Processes for process optimization.

- Multidisciplinary Analysis and Simulation, ensuring the excellence of the designs.

- Structural Integrity Assessment, verifying the safety and optimal performance of the components.

- Fatigue prediction, avoiding premature failures by evaluating useful life.

- Impact and Shock Analysis, helping to improve the resistance of designs.

- Thermal Study, optimizes the response of products to temperature variations.

- Fluid Simulation and CFD, improving the efficiency of flow systems.

- Vibration Analysis, to guarantee the resistance and stability of mechanical systems.

- Design Optimization, finding the best configuration for each project.

- Acoustics and Noise Reduction of sound-sensitive products.

Examples

Analysis of the manufacturing process and its stages, calculation reports, deformations, cost evaluation, decision-making support, etc.